General information on Titanium Anode for Metal Electrowinning

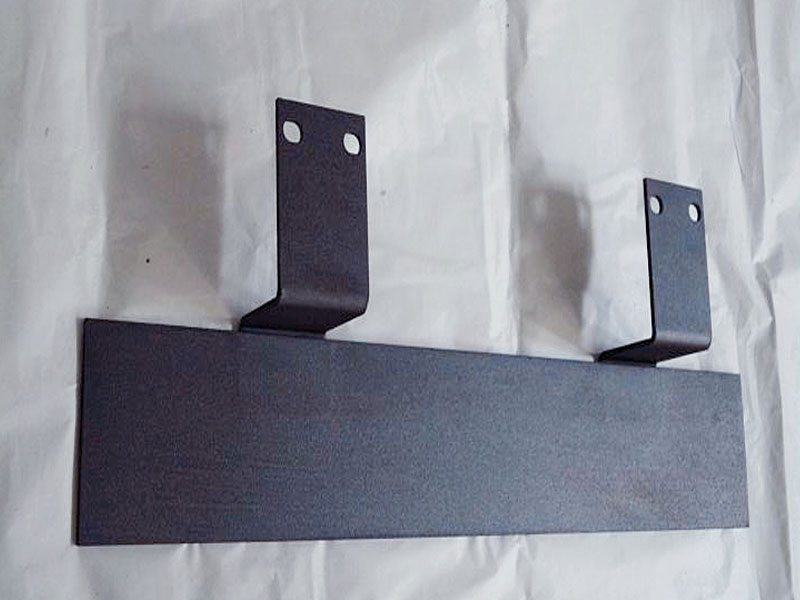

Base Material: Titanium (Gr1, Gr2)

Coating Material: RuO2+IrO2+Pt+X

Electrowinning is the process of the removal of the metal ions from the liquid solution, such as plating baths, and rinse water. The method can use for the recovery of precious metals.

Dimensionally Stable Anode (DSA) in titanium substrate can increase plant cathode output through increased current density operations, improve plant on-stream production, no sludge generated or removed, and improve current distribution producing smooth high efficient cathode. It has been widely applied in metal electrowinning applications for non-ferrous metals recovery such as copper, nickel, cobalt, and zinc.

MMO anodes are exclusively used in the metal recovery system. The system is composed of the deposition of an electrolytic cell at the cathode, in the metal you want to obtain. MMO coated Titanium Anodes that are immersed in a fluidized bed of non-conducting particles, this ensures that there are high levels of mass transport and low power requirements. The metal recovery system is used for the efficient recovery of metals from dilute solutions where conventional electrolysis cannot be considered.

Baoji Yongji Titanium Anode is a certified DSA titanium electrode factory with over 20 years of production experience. With excellent and experienced engineers, they can customize the electrode and provide solution suggestions for your electrowinning plant. Welcome to contact us for details.

Features:

- Light weight compared with the lead anode

- High corrosion resistance

- Fewer byproducts, more harvest efficiency

- Lower cell voltage

Applications

- Metal recovery systems

- Electrowinning Pilot Plant

- Electrowinning of copper, cobalt, nickel, chromium, zinc, and other metals;

GET A QUOTE

Please describe your requirement in as detail as possible, it is useful for us to offer you a better solution.