The Titanium Of Platinised Coating

Basic Parameters:

- The substrate material is: Grade 1 titanium or Grade 2 titanium

- Coating Material: Platinum (Purity 99.99%)

- Shape: rod, strip, disc, plate, mesh, wire, tube or combinations and or assemblies (customized)

- The current density: is <8000 A /㎡.

- Hydrohydrochloric Environment: <20%

- Coating thickness is: 0.2-15 μm

- Noble Metal Content: 21-48 g/㎡

- Temperature: <80 ℃

- PH Value: 1-12

Platinized titanium anode can be taken as a high-quality and economical substitute for the Platinum anode. It is made up of titanium substrate material and platinum-plated (0.5~5um) titanium substrate material. Platinized titanium anode integrates good physical and chemical properties of platinum and titanium.

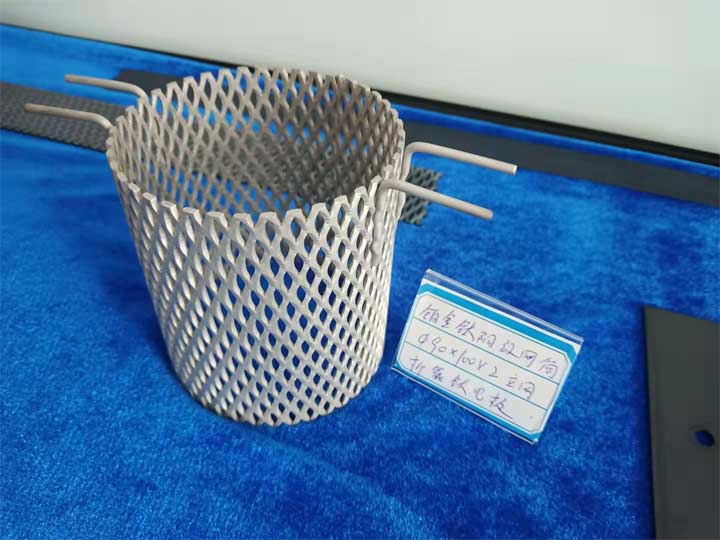

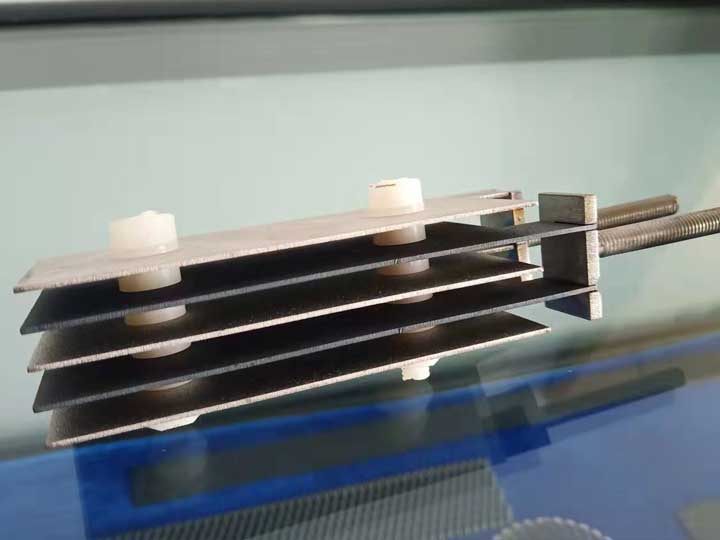

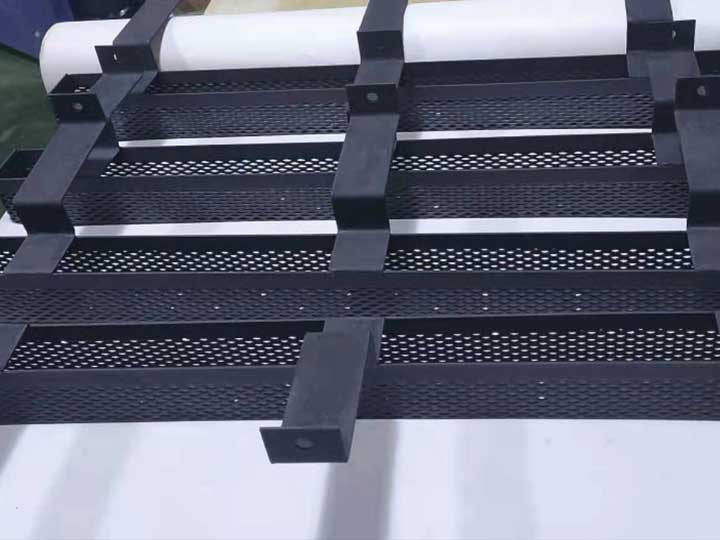

We make the platinized titanium anodes in the shapes of mesh, plate, rod, tube, and other complex shapes. Mesh and plate are normally in plating, electroanalysis, and water treatment. Rod and tube are normally used in cathodic protection. We have leading technology in platinized titanium anodes which are very smooth on the anode surface and can be a nice substitute for the pure platinum anode.

Features:

- High performance of corrosion resistance

- High efficiency of current

- Long Service Life

- The substrate can be restored when the anode loses its activity

- High current density, and high production efficiency

- Low weight

Applications

- Cathodic Protection. With high current densities, for example, Seawater intakes, Heat exchangers & Condensers, Jetties & Tanks, Water Heaters

- Electrosynthesis

- Electroplating Industries. Such as Precious metal plating, Gold plating, Electrolytic Cells, Rhodium Plating, Sensing Elements, Electro galvanizing, Electro chlorination, Hard Chrome Plating, Wastewater treatment, Precious Metal Recovery, Rotogravure printing

- Electro-Dialysis With Reversal Of Polarity

- Water Ionizer