Titanium with a Ruthenium Mixed Metal Oxide coating

Basic Parameters:

- The substrate material is: Grade 1 titanium or Grade 2 titanium

- Coating Material: Mixed Ruthenium-Iridium Oxide

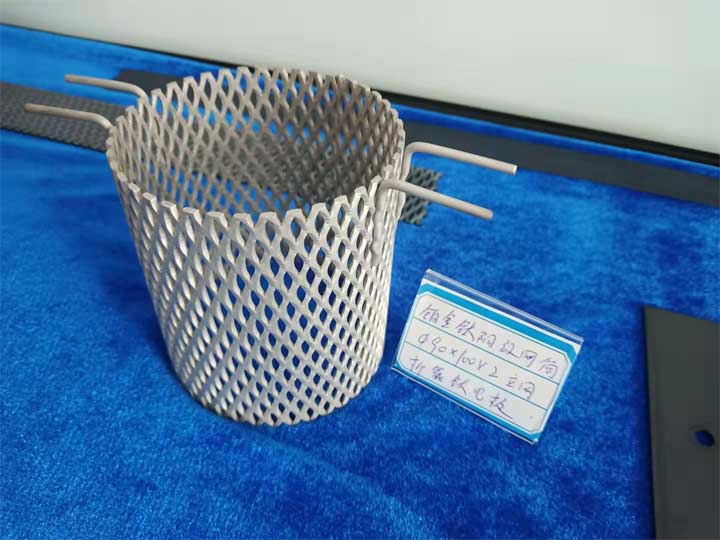

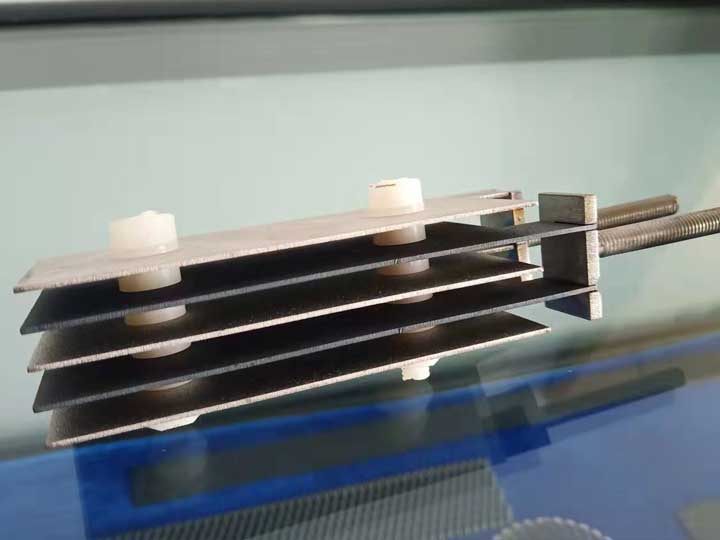

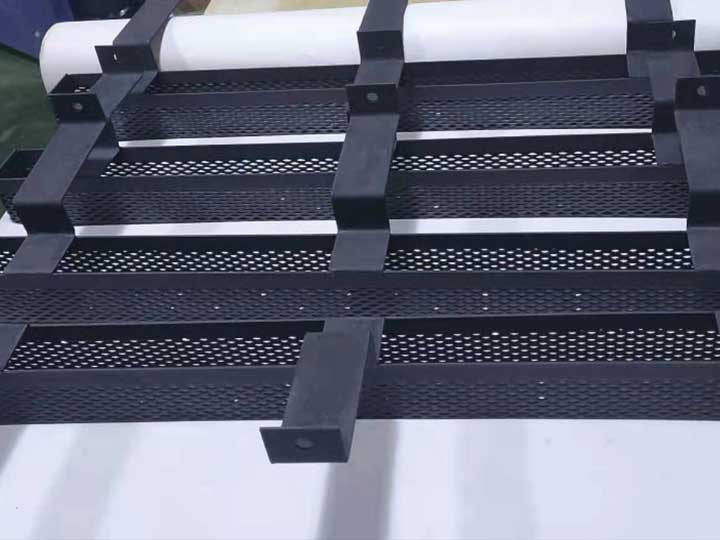

- Shape: rod, strip, disc, plate, mesh, wire, tube or combinations and or assemblies (customized)

- The current density: is <2000 A /㎡. General 200-300A /㎡

- Hydrohydrochloric Environment: <20%

- Compound precious metals content is: 5-20

- Coating thickness is: 5-20 μm

- Noble Metal Content: 8–25 g/㎡

- Content of florin ions: < 50 mg/L

- Temperature: <60 ℃

- PH Value: 1-12

| Coating | Oxygen revolution potential | Suitable working environment |

| Mixed Ruthenium and Iridium | <1.13V | The solution contains Cl-, PH>=7 |

| 8grams/m2 | 10grams/m2 | 12grams/m2 | 15grams/m2 | 20grams/m2 |

| 6,000 hours | 8,000 hours | 10,000 hours | 12,000 hours | 13,500 hours |

Working Parameters for Ru-Ir Coating

| Current density | Temperature | Chlorine concentration | Polarity reversal | Reversal frequency |

| <500A/m2 | 40-60°C | About 30grams/liter | suitable | 2-4 hours |

Applications

- Sodium Hypochlorite Generator

- Electrotonic Chromatography

- Cathodic Protection

- Disinfection Of The Swimming Pool

- EDI-Demineralizing Equipment

- Copper Recovery

- Wastewater Degradation(hospital, breeding, dye, city, etc.)

- Oilfield Wastewater Treatment

- Circulating Water System

- Air Conditioning

- Chlorine Dioxide

- Noble Metal Plating

- Seawater Desalination

- Alkali Production

- Organic Synthesis

- Fruit And Vegetable Machines

Attentions

- The requirements for installation of the electrolytic cell

- Processing conditions, such as electrolyte composition, temperature, current density, and life span

- Mechanical load of titanium anode

- Electric conductivity ability of substrate material