General information on ruthenium-coated titanium anodes

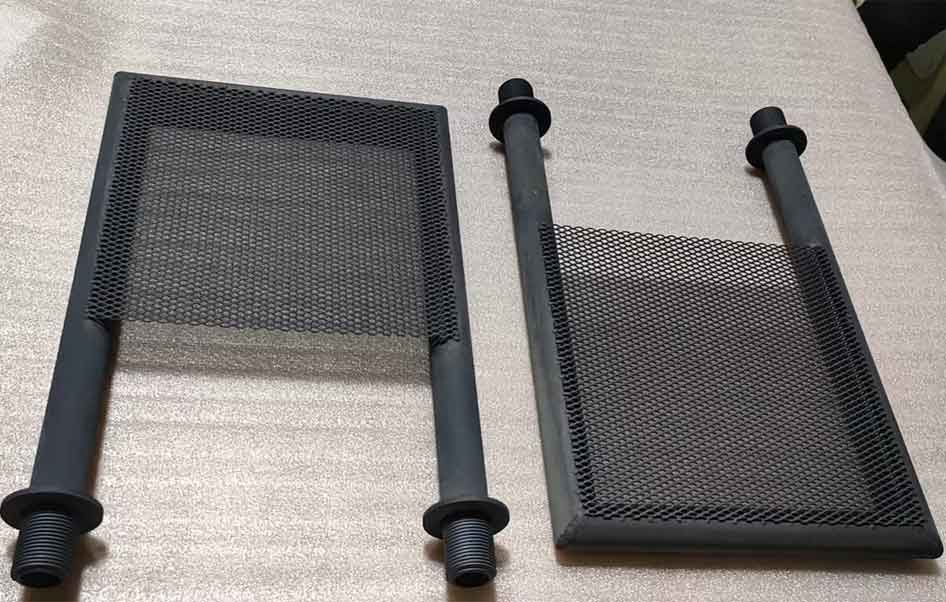

Shape Available: rod, strip, disc, plate, mesh, wire, tube, or combinations. (Customized)

Base Material: Titanium (Gr1, Gr2), Coating Material: RuO2+IrO2+Pt+X

The principle of electrolysis chlorine dioxide generator is to produce mixed disinfection gases such as chlorine dioxide, ozone, chlorine QI, and hydrogen peroxide by electrolysis with a salt separator. The raw material used is generally industrial salt (NaCl) with purity ≥99.10%.

Technical parameters

- Solution: 25%~30% saturated sodium chloride solution

- Current density: ≤1500A/M2

- Anode coating: Ruthenium system mixed oxide coating

- Specifications: anode and cathode with specifications, mesh

- Service life: not less than 5 years

- Other requirements: anode double-sided coating, no burrs around, strictly according to the drawing processing

Application scope

Disinfection treatment of various sewage treatments;

Sterilization and disinfection of swimming pool and bath water;

Algae removal and sterilization of cooling circulating water used in power plants, boilers, and other industries;

The electrolysis electrode plate plays a very important role in the process of producing chlorine dioxide and other gases. As the main component of sodium hypochlorite generator, the quality of the electrode plate determines the electrolysis efficiency and cost of the equipment.

Therefore, users should pay special attention to the material of the electrode when choosing, so what kind of titanium anode is suitable for a chlorine dioxide generator?

Titanium anode for electrolysis of chlorine dioxide has the following advantages

- When the titanium anode electrolysis method is used to produce chlorine dioxide, it also generates O3, CL2, H2O2, and other kinds of strong oxidation and widespread sterilization ability, and the disinfection effect is far better than that of the chemical method.

- Electrolysis disinfection cost is low.

- Good safety, production of raw materials transportation, storage, and operation safety. The chemical process of chlorine dioxide uses chlorine gas, which is very inconvenient to transport and store, and more importantly, poses great safety risks.

- The source of raw materials is easy: the electrolysis method to produce chlorine dioxide, the principle is to use titanium anode electrolytic salt water, compared with chlorine gas, salt water is more convenient, safer operation. Baoji Yongji Titanium Anode for many years of research and development, the anode assembly for chlorine dioxide generator is made of noble metal coatings such as ruthenium and iridium, with stable performance, high electrolytic efficiency, free of cleaning and corrosion resistance. It is the ideal electrode material for chlorine dioxide generators, and its products are exported to many countries around the world.

- In the process of communication with the customer, our company fully understood the customer’s use conditions and requirements and prepared a special oxide coating for the chlorine dioxide generator anode, which has stronger corrosion resistance. Will have the sample life test before delivery, it meets the customer’s requirements and standards.

GET A QUOTE

Please describe your requirement in as detail as possible, it is useful for us to offer you a better solution.